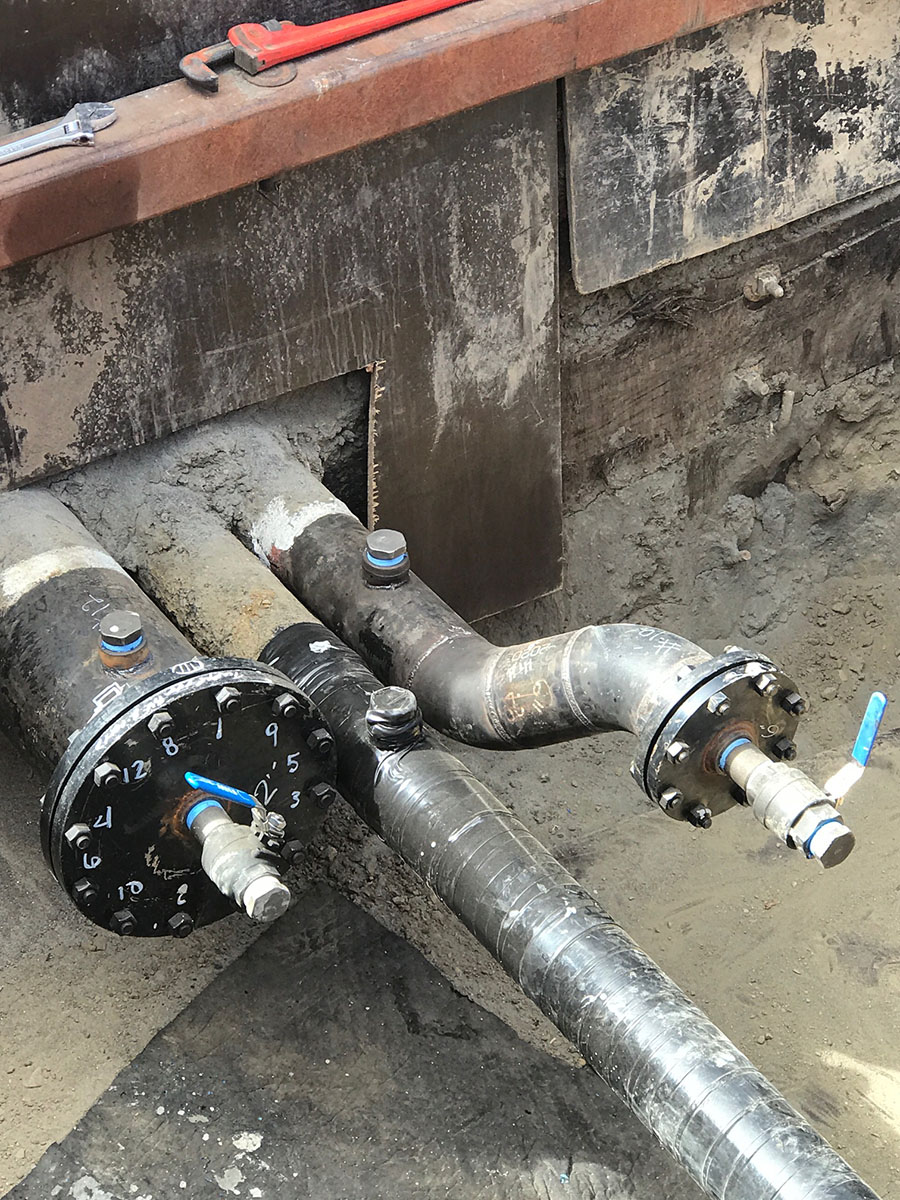

Shell Pipeline, Portland, OR

- Category

- Abandonment

About The Project

PROJECT LOCATION

Portland, Oregon

CLIENT

Shell Oil Company

COMPLETION DATE

2016

The Shell dock-unloading pier in Portland, OR was no longer in use. Multiple gas lines were built over the years from the old dock to the gas storage facility (approx. 2,500’ away). These six lines went under a major railroad car manufacturer and the production schedule couldn’t be stopped to abandon them. When using a controlled density fill (CDF), the maximum distance to flow material is 300’. An abandonment with CDF would’ve halted railcar production and added weeks—if not months—to the abandonment process schedule.

The Solution

Cell-Crete was contacted by the general contractor with knowledge of the flowable nature of low-density cellular concrete (LDCC). The lines were cleaned of any excess fuel, and the general contractor created bulkheads at each end to push LDCC until it was completely full. Cell-Crete monitored pressure in lines to minimize the potential for bulkhead leakage or heaving. All lines were completed in one day with an extra day to fill any auxiliary lines.