Lightweight Insulating Concrete Roof Systems

Lightweight Insulating Concrete (LWIC) is a cutting-edge roofing solution that seamlessly integrates two longstanding and proven materials, Lightweight Concrete and Polystyrene Insulation Board, to provide a highly effective and durable roof system. By pouring a specialized lightweight concrete mixture onto the roof deck, LWIC forms a durable and insulating layer that significantly enhances energy efficiency and thermal performance. Its remarkably low thermal conductivity minimizes heat transfer, resulting in reduced energy consumption and optimized life cycle costs. With exceptional wind uplift resistance, LWIC ensures superior protection and structural integrity even in the most extreme weather conditions. Furthermore, its non-combustible nature offers enhanced fire resistance, making LWIC a safe and dependable choice for any construction or retrofit project. Choose LWIC for an advanced roofing solution that excels in resilience, sustainability, and performance.

LIGHTWEIGHT INSULATING CONCRETE INSTALLATION PROCESS

HOW IS LWIC INSTALLED

1. Clean substrate and spread a ¼” min thick LWIC slurry evenly over substrate.

2. Follow board layout and place holey board accordingly to achieve positive drainage.

3. Apply a minimum of 2” LWIC material over the holey board completely covering the surface.

4. Wait 48-72 Hours to allow material to cure

5. Apply roofing membrane to LWIC surface following manufacturer recommendations.

CONCRETE ON A ROOF?

In the construction industry, concrete is often known for its heavyweight characteristics. However, Lightweight Insulating Concrete (LWIC) offers a much lighter alternative compared to standard concrete. The weight reduction is achieved by incorporating air entrainment or lightweight aggregate into the concrete mix. Interestingly, in an LWIC system, only the top 2-3 inches consist of actual concrete, while the majority of the system is composed of EPS holey board, which further contributes to reducing the overall assembly weight. LWIC is typically cast at a density of 42 pounds per cubic foot (PCF), which is less than half the weight of standard lightweight concrete that usually weighs between 90-115 PCF. Consequently, an average R-30 system with a 9-inch thickness weighs approximately 7.5-8.5 pounds per square foot (PSF)!

WHAT’S IN THE MIX?

WHY SHOULD I CHOOSE LWIC?

- Lower Overall Cost:

Lightweight Insulating Concrete (LWIC) roof deck systems offer a cost-effective alternative when compared to other options like tapered polyiso and cover board assemblies. The EPS insulation is slurried into place and bonded to the substrate. No mechanical fasteners are required. Once the LWIC Roof Deck is cast, installation of the membrane is continuous and fast. The reduced cost of LWIC roof decks makes them an attractive choice for projects that require efficient and affordable roofing solutions without compromising on performance and durability, their resilience proves to be the correct choice for roofing applications. - High R-Values:

LWIC roof deck systems utilize EPS insulation boards (Holey board) that possess exceptional R-values. This means that they provide excellent thermal insulation, reducing heat transfer and energy loss from the building. The holes in the board which account for 3% per volume allow the LWIC to flow into these voids and create a complete one piece roofing system. - Lower Life-Cycle Costs:

Typical roof rigid insulation boards tend to absorb moisture over time, which diminishes their insulation effectiveness. Studies have demonstrated that rigid insulation boards lose approximately 4% of their R-value each year. In contrast, LWIC maintains its R-value for the entire lifespan of the building, ensuring consistent thermal insulation without any degradation. This is in large part attributed to the resilience of the lightweight insulating concrete that protects both the roofing membrane and the holey board from thermal stress over time. LWIC roof decks serve as a permanent insulation system that can last for the entire lifespan of the building. LWIC roof decks significantly lower the overall cost of maintaining and managing the building’s roof by eliminating the need for frequent roof replacements. - Reroofability:

Should the need for reroofing arise, LWIC roof decks simplify the process. In traditional Rigid insulation board systems they typically require total tear-off in re-roofing applications. This is because the board has lost its strength and insulation value. Total tear-off is risky and can pose a threat to the building’s interior. A great deal of debris must be hauled to landfills – a costly operation which is time consuming and environmentally unacceptable. With LWIC only the roofing membrane needs to be replaced, while the existing LWIC substrate remains in place. This feature saves time, labor, and costs associated with the reroofing process, making it a convenient and cost-effective solution. - Warranty:

LWIC roof deck systems come with warranties offered by major roofing manufacturers. These warranties provide assurance and peace of mind to building owners and stakeholders, guaranteeing the quality, performance, and durability of the roof system. - Hourly Fire Ratings:

LWIC is a non-combustible material, making LWIC roof deck systems inherently fire-resistant. These roof systems hold an hourly fire rating, eliminating the need for additional fireproofing measures on the underside of the roof deck; Since the flutes are filled, this fire channel is eliminated. By reducing the requirements for fire protection, LWIC roof decks effectively minimize costs associated with safeguarding the building structure. - Wind Uplift:

LWIC roof decks exhibit excellent performance in terms of wind uplift resistance. Acting as an air retarder, these roof decks effectively mitigate the impact of wind forces, providing enhanced structural stability and protection against wind-related damage. - Faster Construction:

The installation process for LWIC roof decks is significantly faster compared to traditional roofing systems. This time-saving advantage can help streamline construction schedules, reduce labor costs, and accelerate project completion, thus improving overall efficiency. With LWIC roof decks, the application of the roofing membrane can commence as soon as 48 hours after the casting process. This minimizes exposure time and ensures swift progress in the construction timeline. - Customizable Slope-to-drain:

LWIC roof decks eliminate the issue of standing water on the roof surface. By providing versatile customizable slope-to-drain designs, these roof decks enhance water drainage, preventing water accumulation and potential damage to the roofing membrane. This feature significantly contributes to the longevity and performance of the new membrane.

LWIC roof decks offer a high degree of versatility in terms of their installation options. They can be placed over various substrates, including concrete, wood or steel decking. Additionally, LWIC roof decks provide exceptional impact resistance, with the ability to withstand pressures of 160 pounds per square inch (psi) or even higher. This versatility ensures compatibility with diverse construction requirements and enhances the overall resilience and sustainability of the roof system.

COMPARING POLYISOCYANURATE ROOF SYSTEMS TO LWIC ROOF SYSTEMS

When it comes to roofs, the most common method used today are polyisocyanurate roof systems. However, there are several advantages to consider when making the switch to a Lightweight Insulating Concrete (LWIC) roof system. Let’s take a look at the comparison below:

Poly-iso Tapered System

- Multiple layers of insulation required to achieve slope. This slows production and increases costs due to the need for adhesives and fasteners to keep the poly-iso secured to the roof.

- Multiple layers of insulation also means a lot of custom cuts especially around penetrations, this slows down production. Gaps between board and metal fasteners create a thermal conduit between the deck and outside conditions which decreases R-Value.

- Costly cover board used to hide the shrinkage of polyiso over time.

- Water is detrimental to Poly-iso, any failure in your roofing membrane means a possible interior leak. It also means replacing your roof as far as the water spreads.

- Replacement of roofing membrane over time will require a complete tear off of the membrane as well as the coverboard and insulation.

LWIC Roof System

- Polystyrene insulation can be cut up to 48″ in thickness, eliminating the need for multiple layers. This means that the first row of insulation can be installed as quickly as the last.

- LWIC is a flowable material that is placed using a concrete hose. By incorporating air entrainment or lightweight aggregate in the mixture, the LWIC becomes lightweight while providing R-Value. This not only protects and encapsulates the polystyrene insulation but also creates a permanent slope.

- Any gaps left behind due to imperfections or custom cuts are filled with the flowable LWIC, resulting in a monolithic system that eliminates thermal conduits.

- LWIC has low permeability, meaning that if there is a leak in the membrane and a positive slope, the LWIC will not absorb the water and will protect the polystyrene insulation underneath. In such scenarios, it may be possible to only replace the roof membrane rather than the entire roof system.

- Over time, if the roofing membrane needs to be replaced, only the membrane itself needs to be replaced with an LWIC roof system. The LWIC provides a resilient material that maintains its integrity for the lifespan of the building.

GET A FREE QUOTE TODAY

See how you will benefit from using Lightweight Insulating Concrete in your next project!

Send us your electronic plans in CAD of PDF along with any R-value requirements and we will provide you with a preliminary board layout showing slope to drain, minimum and average R-value and thickness along with a complementary budget for the project.

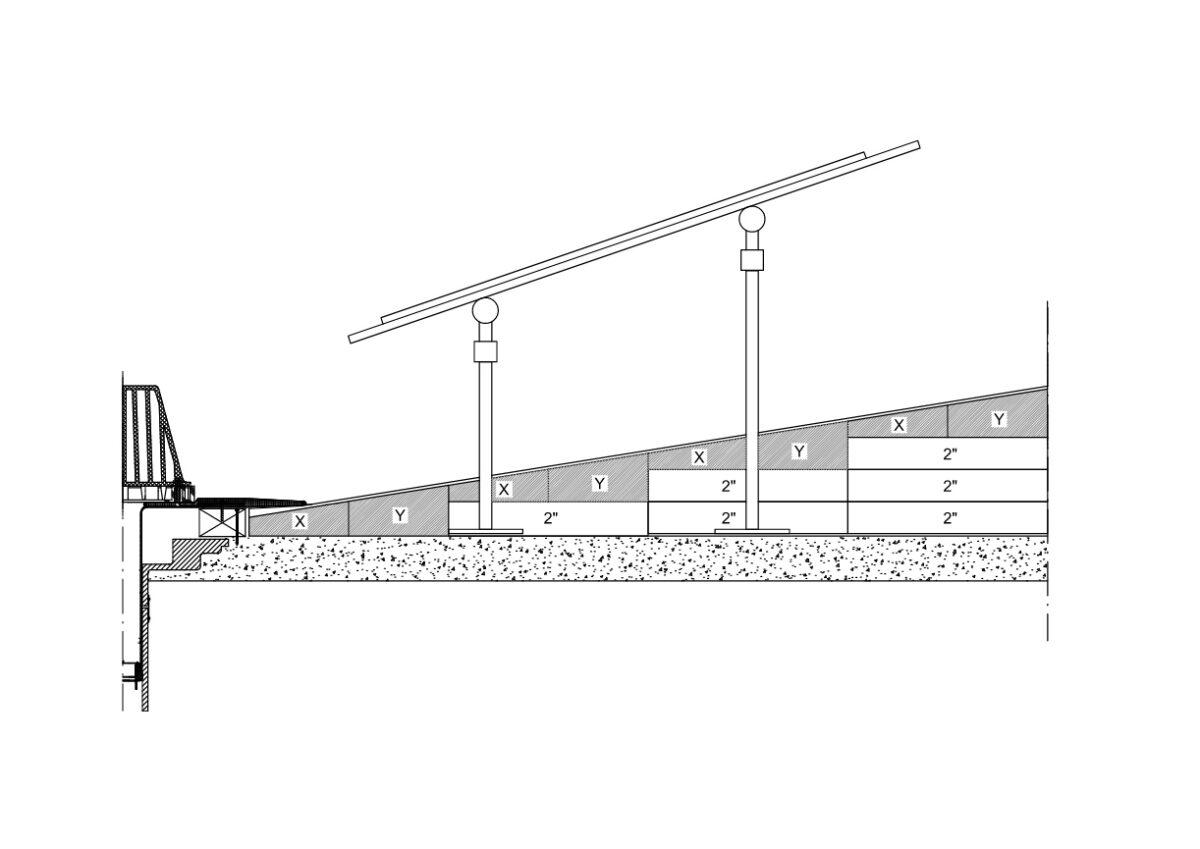

Architect’s Proposed Slope Layout

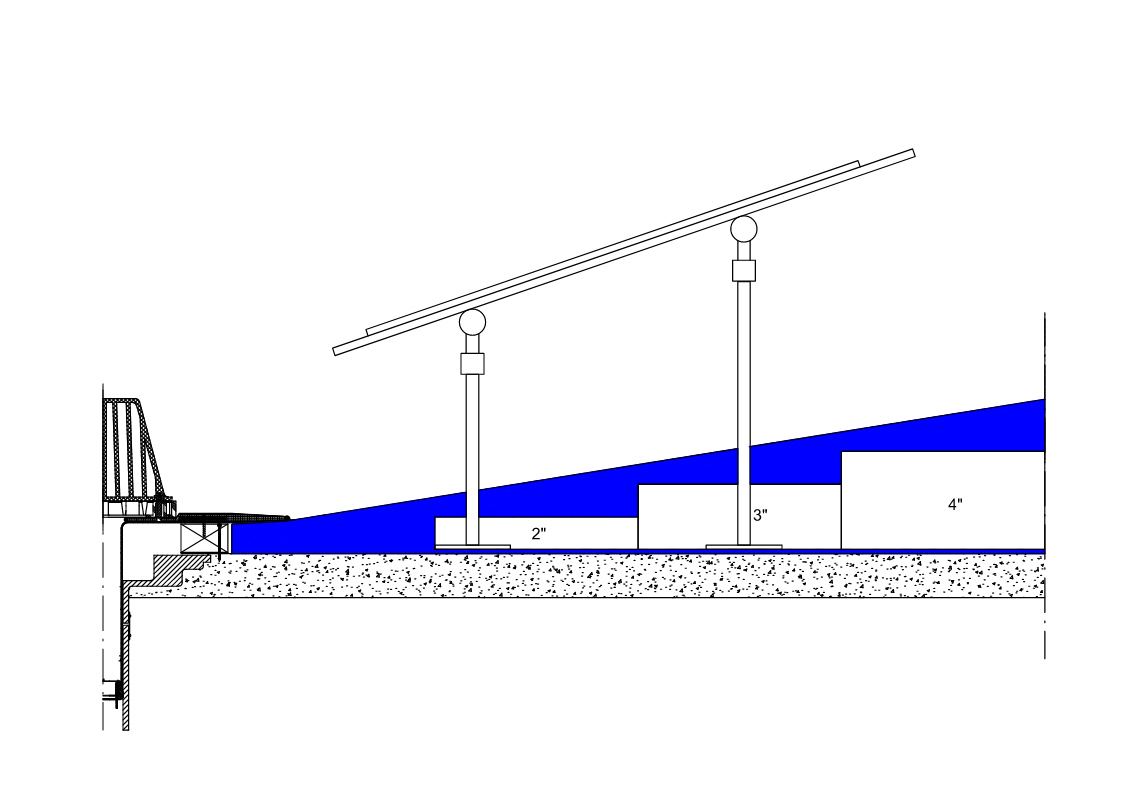

Cell-Crete’s EPS Board Layout