Lightweight Insulating Concrete Roof Decks

Lightweight Insulating Concrete (LWIC) Roof Decks are composite systems cast over galvanized metal decks, structural concrete, wood decks, or existing roof systems using LWIC and Expanded Polystyrene (EPS). LWIC slurry contains Portland cement, water, and preformed foam. There are two predominant types of LWIC: Cellular or Aggregate. LWIC encapsulates Expanded Polystyrene (EPS) insulation boards which are laid out in a stepped pattern custom-tailored to each job to achieve the specified slope and R-value (thermal resistance). The LWIC composite system provides a surface to attach the new roof membrane. No cover boards are required or vapor barriers. The LWIC composite system can provide FM and UL ratings, both wind and fire. LWIC’s additional benefit is that it greatly reduces any air infiltration and creates a heat sink that locks in the R-Value and reduces membrane thermal shock to prolong the life of the new roof membrane.

HOW DOES LWIC COMPARE?

The most common alternative to structural sloping in today’s market is using tapered polyisocyanurate. Traditional roof insulation systems such as polyisocyanurate are not as durable, wind resistant, or cost-effective over the long-term as LWIC.

- Durable: Encapsulating Lightweight Insulating Concrete preserves R-value of polystyrene insulation as well as creates permanent slope. Other methods use costly cover board to hide the shrinkage of polyisocyanurate over time. You will need to replace polyisocyanurate every time you replace your roofing due to age or failure while a cellular concrete substrate lasts the life of the building.

- Wind-resistant: LWIC systems are known for their strong performance history of resistance to high wind loads. The concrete slurry coat bonds the system to the structural substrate, helping to provide high wind load resistance.

- Cost-effective: EPS boards can be cut up to thicknesses in excess of 48”, meaning you only need one layer of insulation to meet your desired slope. Other materials require multiple layers of insulation to achieve desired slope, slowing production and increasing costs with large amounts of expensive adhesive or extra-long specialty fasteners.

LIGHTWEIGHT INSULATING CONCRETE INSTALLATION PROCESS

LIGHTWEIGHT INSULATING CONCRETE BENEFITS

✓ High R-values providing less stress on the roof

✓ Customizable slope-to-drain to meet drainage needs

✓ Improved fire resistance with high hourly fire ratings

✓ Lower roof replacement and life-cycle costs

✓ Versatile product that can be placed over concrete, steel, or wood decking

HOW MUCH DOES LWIC WEIGHT?

Concrete tends to by synonymous with heavy weight in the construction industry. Lightweight Insulating Concrete (LWIC) however weighs only a fraction of what standard lightweight concrete does. With Polystyrene Insulation making up the bulk of the LWIC system the weight is cut even further. The LWIC is cast at a density of 42 PCF. That’s less than half of the weight of standard lightweight concrete at 90-115 PCF. Therefore an average R-30 system with a 9” average system thickness only has a weight of 7.5-8.5 PSF!

SAVE TIME

LWIC roof decks take less time to install than traditional roof insulation systems. EPS boards are cut in various thickness to meet your slope needs That means your first row of insulation goes down as quickly as your last. Methods that require multiple layers of insulation slow down production.

SAVE MONEY

Faster install times means lower install costs. In addition, building owners can save money on fireproofing and air barrier installation. LWIC systems are fireproof and the system of insulating concrete and EPS insulation acts as a built-in air barrier, maximizing the performance of the insulation.

GET A FREE QUOTE TODAY

See how you will benefit from using Lightweight Insulating Concrete in your next project!

Send us your electronic plans in CAD of PDF along with any R-value requirements and we will provide you with a preliminary board layout showing slope to drain, minimum and average R-value and thickness along with a complementary budget for the project.

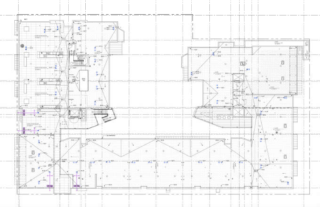

Architect’s Proposed Slope Layout

Cell-Crete’s EPS Board Layout