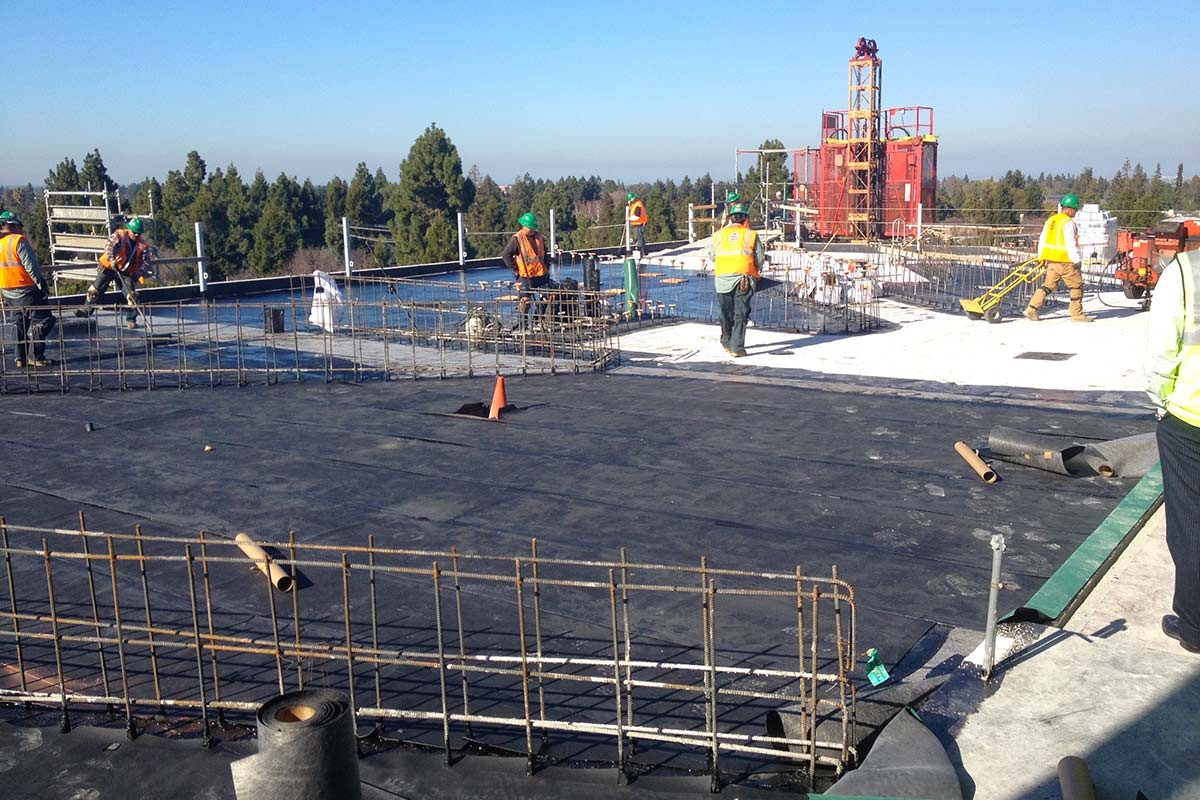

Hot Rubber LWIC System

- Category

- Podium Decks

About The Project

COMPLETION DATE

2018

Lightweight Insulating Concrete (LWIC) and cement board came from a need in the Hot Rubber Asphalt (HRA) Waterproofing industry to provide a slope in structural concrete deck applications. They would typically place the HRA over a flat concrete deck, but in today’s market, this type of application has been modified to require the decks to be a positive slope and ensure proper drainage.

It costs time and money to form up structural decks for an adequate slope. This lead to the marriage of the HRA and LWIC. The LWIC could provide the slope required, and give the much needed R-Value to the project.

The Solution

Initially, there was a problem because the LWIC couldn’t take the high heat from the HRA application. Typical HRA applications require a minimum of 2500 psi structural concrete. This problem was solved by adding a layer of ¼” cement board to the top of the LWIC as a heat shield, which allowed the HRA to be installed without delaminating from the LWIC (caused by the high-flash heat of the HRA).

Cell-Crete has been installing LWIC and cement board since 2013. Our biggest project of the garden roof areas at Stanford’s New Hospital and the adjoining parking structure garden area has been completed. We worked under two separate roof contractors: Letner and Courtney Waterproofing, and the Clark/McCarthy joint venture was the general contractor for the job.